Kwa maloboti akumafakitale, kugwiritsa ntchito zida ndi imodzi mwazinthu zofunika kwambiri pakugwirira ntchito kwawo.Monga mtundu wa zida zogwirira ntchito zogwiritsa ntchito mosiyanasiyana, kumaliza bwino ntchito ya loboti yamakampani mwachindunji kumadalira njira yolumikizira.Chifukwa chake, njira yotsekera kumapeto kwa loboti iyenera kupangidwa molingana ndi ntchito zenizeni komanso zofunikira za malo ogwirira ntchito.Izi zimabweretsa kusiyanasiyana kwamitundu yamakina a clamping.

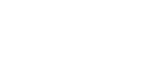

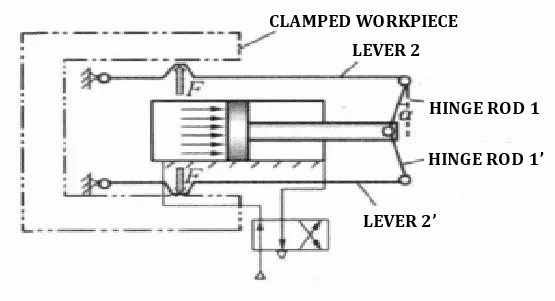

Chithunzi 1 Ubale pakati pa zinthu, mawonekedwe ndi magawo a zotsatira zomaliza Njira zambiri zomangirira makina ndi zala ziwiri zala, zomwe zitha kugawidwa kukhala: mtundu wozungulira ndi mtundu womasulira molingana ndi kayendedwe ka zala;njira zosiyanasiyana clamping akhoza kugawidwa mu thandizo lamkati Malinga ndi makhalidwe structural, akhoza kugawidwa mu pneumatic mtundu, magetsi, mtundu hayidiroliki ndi ophatikizana clamping limagwirira.

Pneumatic end clamping mechanism

Gwero la mpweya wa ma pneumatic transmission ndilosavuta kupeza, liwiro lochitapo kanthu liri mwachangu, sing'anga yogwira ntchitoyo ndiyopanda kuyipitsidwa, ndipo fluidity ndi yabwino kuposa ma hydraulic system, kutayika kwapanikizidwe ndikochepa, ndipo ndikoyenera kwa nthawi yayitali- mtunda wowongolera.Zotsatirazi ndi zingapo manipulators pneumatic:

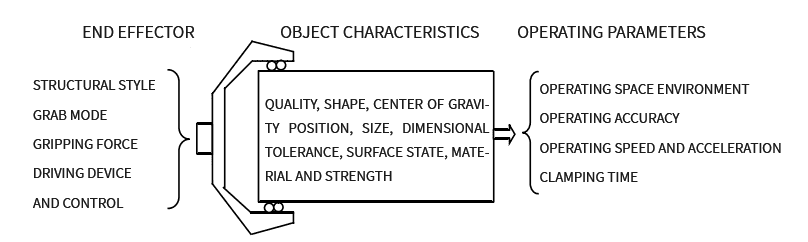

1. Rotary link lever-type clamping mechanism Zala za chipangizochi (monga zala zooneka ngati V, zala zopindika) zimakhazikika pamakina otsekera ndi ma bolts, omwe ndi osavuta kusintha, kotero amatha kukulitsa kugwiritsa ntchito clamping mechanism.

Chithunzi 2 Rotary link lever mtundu wa clamping mechanism 2. Ndodo yowongoka yamtundu wapawiri ya silinda yomasulira yolumikizira Mapeto a chala ichi nthawi zambiri amaikidwa pa ndodo yowongoka yokhala ndi mpando wokwera chala.Mitsempha iwiri ya ndodo ya silinda yochita kawiri ikagwiritsidwa ntchito, pisitoni imasunthira pang'onopang'ono mpaka pakati mpaka chogwiriracho chikatsekedwa.

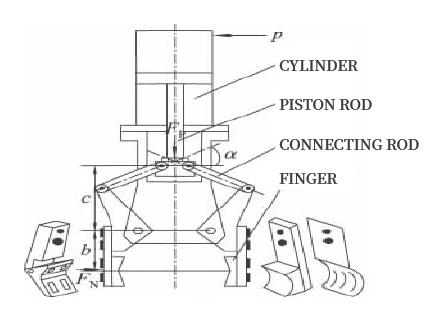

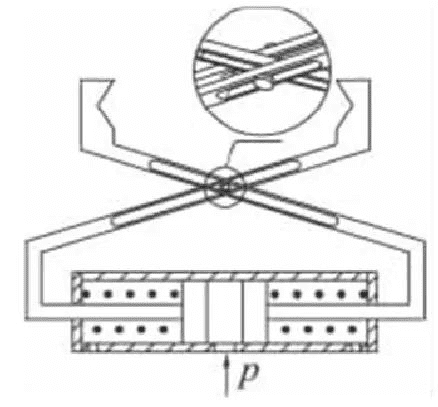

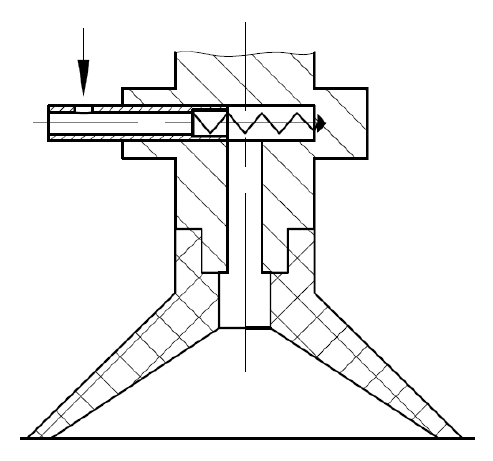

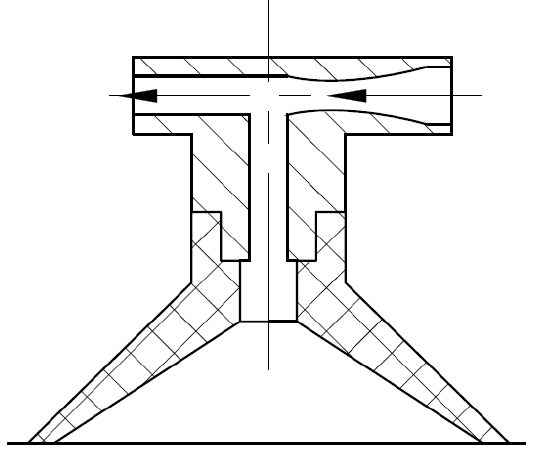

Chithunzi 3 Chithunzi chomangirira cha makina owongoka omasulira amitundu iwiri 3. Njira yolumikizira ndodo yolumikizira yamitundu iwiri nthawi zambiri imakhala ndi silinda yochita kumodzi ndi chala chopingasa.Gasi atalowa mkatikati mwa silinda, idzakankhira ma pistoni awiriwo kuti asunthire mbali zonse ziwiri, potero amayendetsa ndodo yolumikizira kuti asunthe, ndipo nsonga zala zomwe zadutsa zidzakonza zogwirira ntchito;ngati palibe mpweya umalowa mkati mwapakati, pisitoni idzakhala pansi pa zochitika za kasupe Kubwezeretsanso, workpiece yokhazikika idzatulutsidwa.

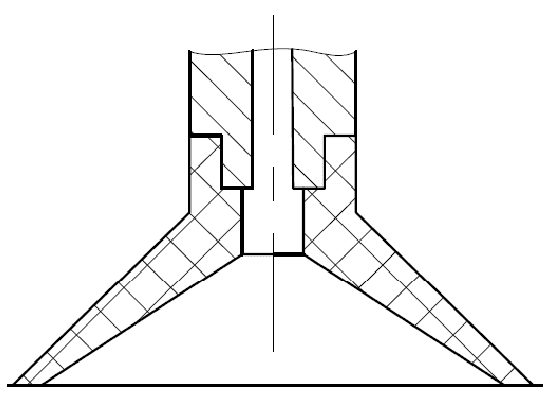

Chithunzi 4. Mapangidwe a njira yolumikizira yomasulira yamitundu iwiri yamitundu iwiri Zopangira zokhala ndi mipanda zopyapyala zokhala ndi mabowo amkati.Makina otsekera akagwira chogwirira ntchito, kuti atsimikizire kuti chikhoza kukhazikitsidwa bwino ndi dzenje lamkati, nthawi zambiri zala zitatu zimayikidwa.

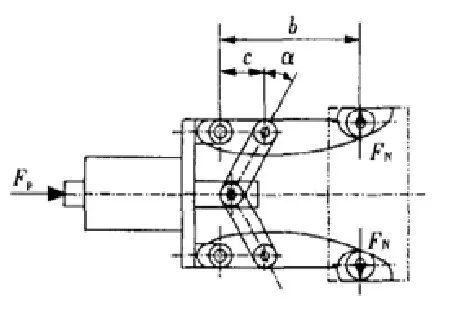

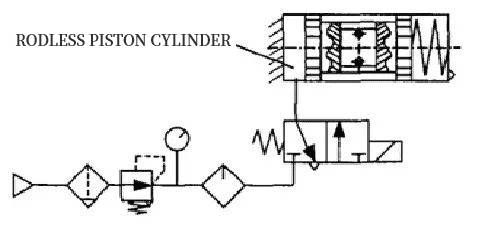

Chithunzi 5 Chithunzi chojambula chachitsulo chamtundu wa lever-clamping ya ndodo yamkati yothandizira 5. Njira yowonjezera yomwe imayendetsedwa ndi silinda ya piston yopanda ndodo Pansi pa mphamvu ya masika, kubwereranso kumazindikiridwa ndi valavu ya solenoid yamitundu iwiri.

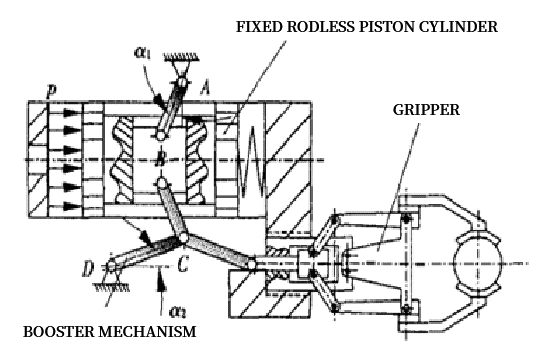

Chithunzi 6 Pneumatic system of fixed rodless piston cylinder Slider yosinthira imayikidwa pamalo ozungulira a pistoni ya silinda ya pistoni yopanda ndodo, ndipo ndodo ziwiri za hinge zimamangirira ma symmetrically malekezero onse a slider.Ngati mphamvu yakunja ikugwira pisitoni, pisitoniyo imasuntha kumanzere ndi kumanja, potero ikukankhira slider kuti isunthe mmwamba ndi pansi.Dongosolo likamangika, nsonga ya hinge B ipanga kusuntha kozungulira kuzungulira nsonga A, ndipo kuyenda mmwamba ndi pansi kwa slider kumatha kuwonjezera kuchuluka kwa ufulu, ndipo kugwedezeka kwa mfundo C kumalowa m'malo mwa silinda yonseyo. chipika.

Chithunzi 7 Njira yolimbikitsira mphamvu yoyendetsedwa ndi silinda ya pistoni yopanda ndodo

Pamene valavu yowongolera ya mpweya woponderezedwa ili kumanzere kumagwira ntchito monga momwe chithunzichi chikusonyezera, khomo lakumanzere la silinda ya pneumatic, ndiye kuti, phokoso lopanda ndodo, limalowa mu mpweya woponderezedwa, ndipo pisitoni imasunthira kumanja pansi. zochita za kuthamanga kwa mpweya, kotero kuti ngodya ya α ya hinge ndodo imachepa pang'onopang'ono.Zing'onozing'ono, kupanikizika kwa mpweya kumakulitsidwa ndi zotsatira za ngodya, ndiyeno mphamvuyo imatumizidwa ku lever ya makina opangira mphamvu zowonjezera mphamvu, mphamvuyo idzakulitsidwanso, ndikukhala mphamvu F kuti igwire ntchito.Vavu yowongolera ikakhala pamalo oyenera, ndodo yolowera kumanja kwa silinda ya pneumatic imalowa mu mpweya woponderezedwa, kukankhira pisitoni kuti isunthire kumanzere, ndipo makina omangira amatulutsa chogwirira ntchito.

Chithunzi 8. The mkati clamping pneumatic manipulator wa hinge ndodo ndi 2 lever mndandanda booster mechanism

Makina awiri a Air suction end clamping

Makina omangirira omata mpweya amagwiritsa ntchito mphamvu yoyamwa yomwe imapangidwa ndi kukakamiza koyipa mu kapu yoyamwa kusuntha chinthucho.Amagwiritsidwa ntchito kwambiri kugwira magalasi, mapepala, zitsulo ndi zinthu zina zokhala ndi mawonekedwe akuluakulu, makulidwe apakati komanso kusasunthika kosasunthika.Malinga ndi njira zopangira mphamvu zoyipa, zitha kugawidwa m'mitundu iyi: 1. Finyani kapu yoyamwa Mpweya womwe uli mu kapu yoyamwa umatsitsidwa ndi mphamvu yotsikira pansi, kotero kuti kukakamiza koyipa kumapangidwa mkati mwa kapu yoyamwa, ndikuyamwa. mphamvu imapangidwa kuyamwa chinthucho.Amagwiritsidwa ntchito kugwira ntchito zokhala ndi mawonekedwe ang'onoang'ono, makulidwe owonda komanso kulemera kopepuka.

Chithunzi 9 Chojambula chojambula cha kapu yofinya 2. Mpweya wotsekemera wotsekemera umatulutsa mpweya woponderezedwa kuchokera ku mpope wa mpweya kuchokera pamphuno, ndipo kutuluka kwa mpweya woponderezedwa kumapanga jeti yothamanga kwambiri, yomwe idzatenge. kuchotsa mpweya mu chikho choyamwa, kotero kuti chikho choyamwa chili mu kapu yoyamwa.Kupanikizika koyipa kumapangidwa mkati, ndipo kuyamwa kopangidwa ndi kukakamiza koyipa kumatha kuyamwa workpiece.

Chithunzi 10 Chithunzi chojambula cha kapu yoyamwa ya airflow negative pressure suction

3. Kapu ya vacuum pump exhaust suction imagwiritsa ntchito valavu yowongolera ma elekitiroma kuti ilumikizanitse pampu ya vacuum ndi kapu yoyamwa.Mpweya ukapopedwa, mpweya womwe uli mu kapu yoyamwa umachotsedwa, ndikupanga kukakamiza koyipa ndikuyamwa chinthucho.Mosiyana ndi zimenezi, valavu yolamulira ikagwirizanitsa kapu yoyamwa ndi mlengalenga, kapu yoyamwa imataya mphamvu ndipo imatulutsa chogwirira ntchito.

Chithunzi 11 Chithunzi chojambula cha kapu ya vacuum pump exhaust suction

Makina atatu a hydraulic end clamping

1. Njira yotsekera yotsekedwa yotsekedwa: Chida chobowola chimakhazikitsidwa ndi mphamvu yamphamvu isanayambe kumangirira kasupe ndipo imatulutsidwa ndi hydraulically.Pamene clamping limagwirira si kuchita tagwira ntchito, ndi boma clamping pobowola chida.Kapangidwe kake kamene kamakhala kuti gulu la akasupe oponderezedwa kale limagwira ntchito yowonjezereka mphamvu monga rampu kapena lever, kotero kuti mpando wotsetsereka umayenda axially, amayendetsa slip kusuntha radially, ndi clamps chida kubowola;mafuta othamanga kwambiri amalowa pampando wotsetsereka ndipo Silinda ya hydraulic yopangidwa ndi casing imakakamiranso kasupe, kuchititsa kuti mpando wotsetsereka ndi slip zisunthire mbali inayo, ndikutulutsa chida chobowola.2. Nthawi zambiri njira yotsekera yotseguka: Nthawi zambiri imatenga kutulutsidwa kwa masika ndi hydraulic clamping, ndipo imakhala m'malo omasulidwa pamene ntchito yogwirayo siinachitike.Makina omangirira amadalira kukankhira kwa silinda ya hydraulic kuti ipangitse mphamvu yothina, ndipo kutsika kwamphamvu kwamafuta kumabweretsa kuchepetsedwa kwa mphamvu yopondera.Nthawi zambiri, loko ya hydraulic yokhala ndi magwiridwe antchito odalirika imayikidwa pagawo lamafuta kuti asunge kuthamanga kwamafuta.3. Makina omangitsa a Hydraulic: Kumasula ndi kupondaponda kumachitika ndi kuthamanga kwa hydraulic.Ngati zolowetsa mafuta za ma silinda a hydraulic mbali zonse zimalumikizidwa ndi mafuta othamanga kwambiri, zotsekemera zimayandikira pakatikati ndikuyenda kwa pisitoni, kutsekereza chida chobowola, ndikusintha Kulowera kwamafuta othamanga kwambiri, zotsekemera zimakhala. kutali ndi pakati, ndipo chida chobowola chimatulutsidwa.

4. Compound hydraulic clamping mechanism: Chipangizochi chili ndi silinda yayikulu ya hydraulic ndi silinda ya hydraulic cylinder, ndipo seti ya akasupe a disc imalumikizidwa ku mbali ya silinda ya hydraulic cylinder.Mafuta othamanga kwambiri akalowa mu silinda yayikulu ya hydraulic, amakankhira chipika chachikulu cha hydraulic cylinder kuti asunthe, ndikudutsa pamzere wapamwamba.Mphamvuyi imaperekedwa kumpando wotsetsereka kumbali ya hydraulic cylinder yothandiza, kasupe wa disc amakanikizidwanso, ndipo mpando wotsetsereka umayenda;nthawi yomweyo, mpando wozembera mbali yayikulu ya hydraulic silinda umayenda pansi pa mphamvu ya masika, ndikutulutsa chida chobowola.

Makina anayi otsekera maginito

Amagawidwa m'makapu a electromagnetic suction ndi makapu oyamwa okhazikika.

Chuck yamagetsi ndiyo kukopa ndi kumasula zinthu za ferromagnetic poyatsa ndi kuzimitsa zomwe zili mu koyilo, kupanga ndikuchotsa mphamvu yamaginito.Chikho choyamwa cha maginito okhazikika chimagwiritsa ntchito mphamvu ya maginito yachitsulo chokhazikika cha maginito kukopa zinthu za ferromagnetic.Imasintha maginito ozungulira mzere mu kapu yoyamwa posuntha chinthu chodzipatula cha maginito, kuti akwaniritse cholinga chokopa ndi kumasula zinthu.Koma imakhalanso yoyamwa, ndipo kuyamwa kwa kuyamwa kosatha sikuli kwakukulu ngati kuyamwa kwa electromagnetic.

Nthawi yotumiza: May-31-2022